The Netherlands aims to be fully circular by 2050. In order to achieve that goal, we already need to use 50% fewer primary raw materials by 2030. At Cialona, we take this ambition seriously and are also very concerned with doing business more sustainably. Not only do we make impressive exhibition stands, but we also do so in the most sustainable way possible.

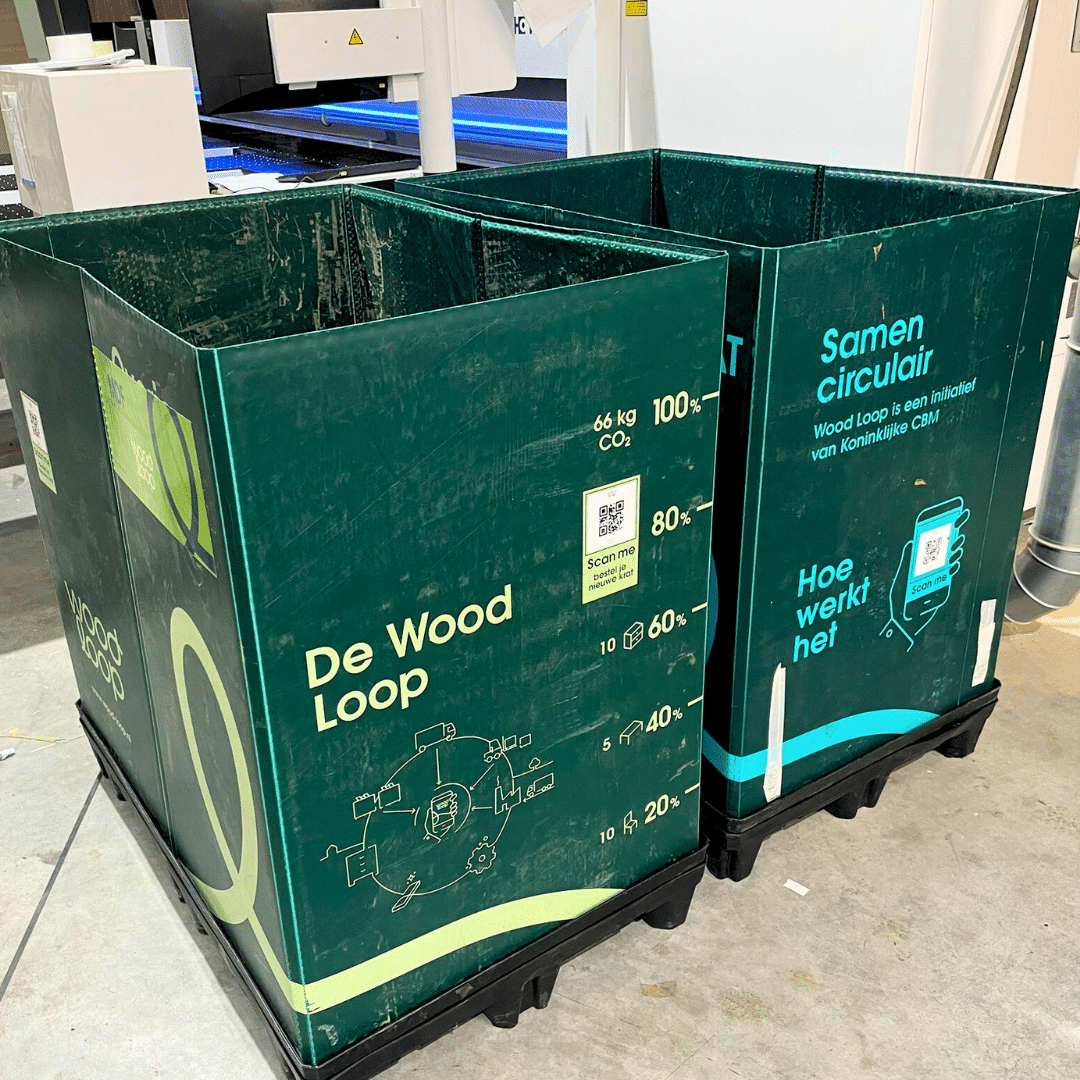

So Cialona’s commitment to innovation and sustainability has led us to a great new partnership with Wood Loop Foundation.

This collaboration brings us closer to a circular future while providing our customers with environmentally friendly stand construction solutions.